Why do every manufacturing unit or factory need machine guards installed on the machines?

What is a machine guard?

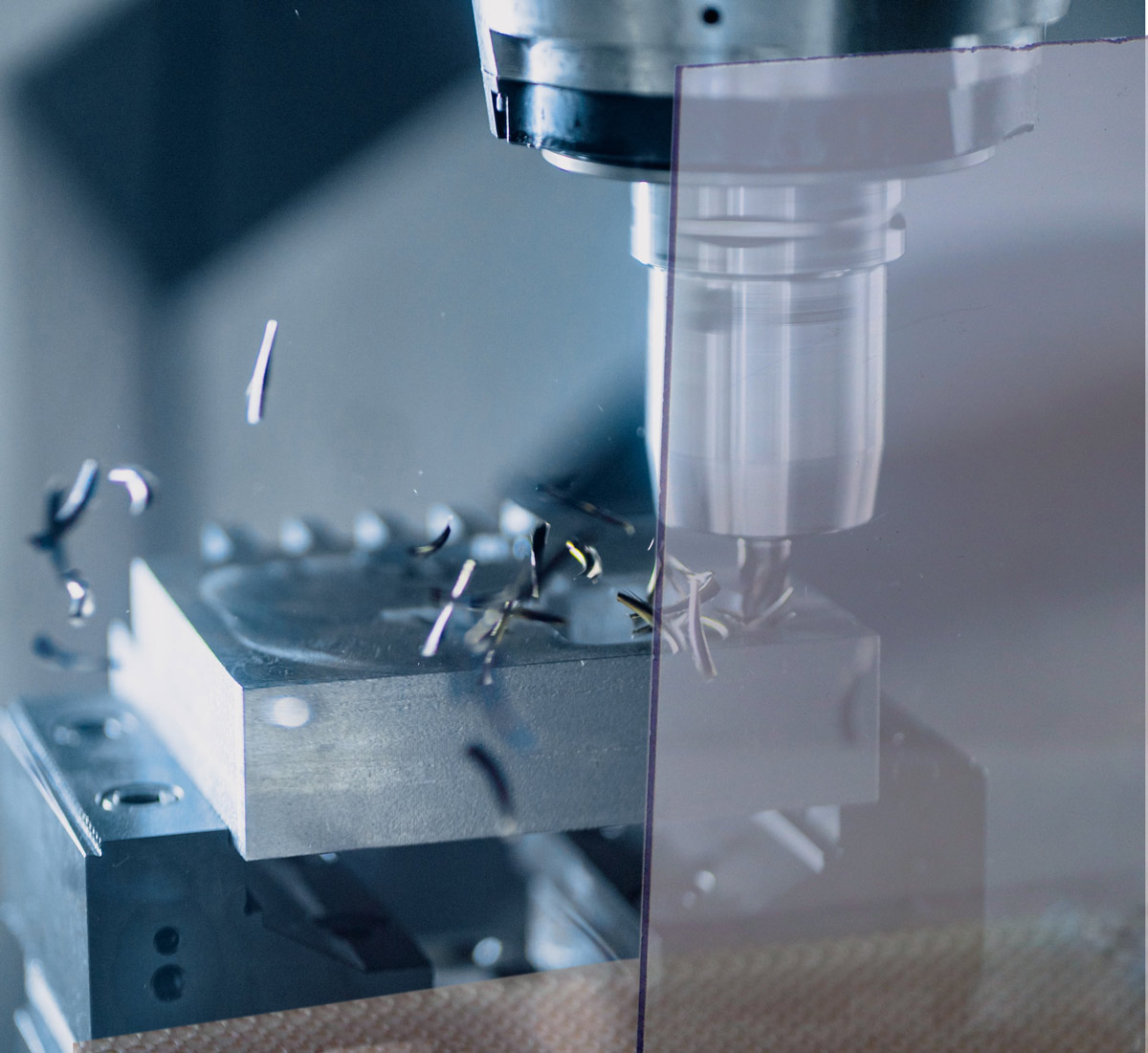

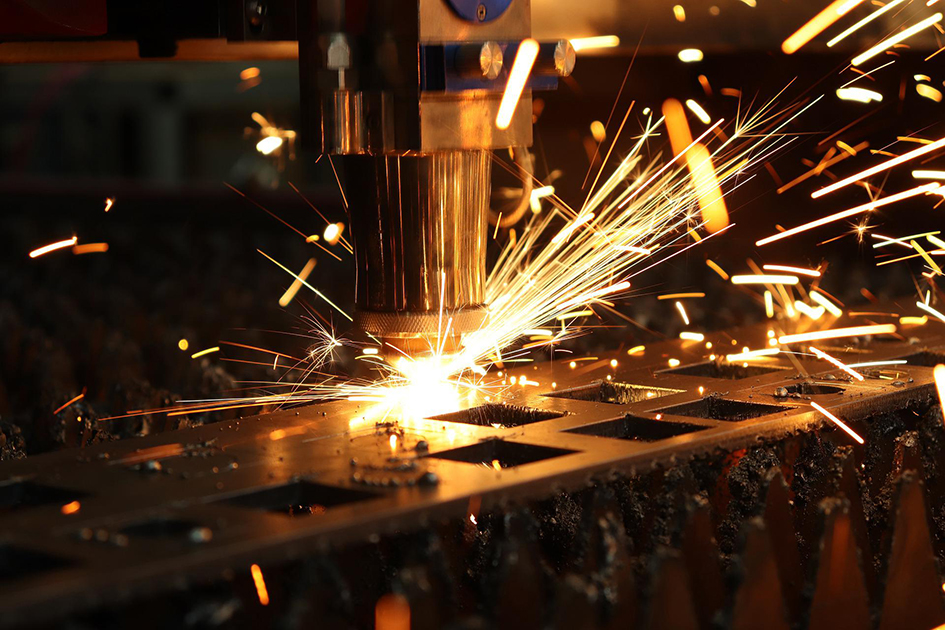

Machine guard is a safety protection cover which can be installed on machines to protect workers/labourers from chips, sparkles, dust, etc. and also to prevent the machines from dust, insects and unnecessary things falling on the running machine.

Why do every manufacturing unit/factory need machine guards installed on the machines?

As stated above, a machine guard is a safety protection cover for the machine itself as well as the human body (workers/labourers working on machines).Chips, sparkles, dust, etc. produced from CNC machines while working can be hazardous. These hazardous effects are dangerous for humans. One can lose his/her eyes or can hurt the skin by the dangerous materials existing from machines. And so it is very important to safeguard one’s self from this hazard.

Secondly, if insects or water enters into the machine lying on the floor or while running then it may cause machine breakdown and stop the production. This results in heavy loss as it affects production and the cost of repairing some machines is very high.

For above mentioned reasons, it’s very important to always have machine guards installed on your machine.

What kind of machine guard is best?

Many companies use heavy steel machine guards which may even turn more dangerous for the labourers/worker working on the machine. These heavy steel machine guards may leave cut marks on their hands or legs and cause injury. Also, Steel machine guards have never been convenient to use as they are very bulky and difficult to lift.

Transparent polycarbonate or acrylic barriers or machine covers are the best way to safeguard workers from hazardous materials. The worker can see through the cover or guard and have an idea about the real time process going on in the machine. So, this is the convenient side of the transparent safeguards.

Secondly, polycarbonate or acrylic barriers are lightweight and can be easily moved and covered the machine again.

Polycarbonate safeguards are sustainable and weather proof. Polycarbonate machine guards last very very long as bad weather, hazardous materials or elements can’t make any impact on the material.

How to get Polycarbonate or Acrylic Machine Guard?

There are two ways to get polycarbonate or acrylic machine guards. One is to purchase from industrial stores. Another way to get the machine guards is to order custom made guards from the fabricators or make your own.

Remember to use Tilara Polycarbonate or Acrylic sheet to make the machine guard or check it while buying from industrial stores. Tilara Sheets have extreme impact strengths and serve your purpose to protect from any hazardous materials. As TilaraSheets are waterproof, the product made from the sheets last very long.

Variety of materials (sheets) are available to make machine guards. Visit the website for the details and choose the right material for your project here: https://www.tilarapolyplast.com/index.html.

Turn their house into a home wit...

Turn their house into a home wit... Corrugated Polycarbonate Sheets ...

Corrugated Polycarbonate Sheets ... Seasonal Variations in Acrylic S...

Seasonal Variations in Acrylic S... How Acrylic Design Sheets Can Tr...

How Acrylic Design Sheets Can Tr... Tips for Finding Affordable Roof...

Tips for Finding Affordable Roof...